Katalog

Biblioteka

-

Combine harvester NEW HOLLAND TC5050 - TC5080

Combines with a floating transporter in the inclined cameraCombine harvester NEW HOLLAND TC5050 - TC5080 The TC5080 combines in comparison with the competitors had higher effective performance. The threshing device in these machines separates to 92% of grain straw and the rotor separator still in addition separates from 3-4% of grain. The threshing drum has the high inertial weight that allows to smooth peak...

Artykuł -

Combine harvester NEW HOLLAND TF 42 - TF 46

Combines with wide gripping cutting platform (1982-1995)Combine harvester NEW HOLLAND TF42 - TF46 Implementation in production of combine harvesters of the TF series was necessary for the end of 1982. These combines were noted by the equipment hydraulic transmission and widely - gripping cutting platform. In a design of combines the highly effective scheme of the thresh which provides the low wastage rate,...

Artykuł -

Combine harvester NEW HOLLAND TF 76 - TF 78

Combines with complete control of technological procedure (1994-2002)Combine harvester NEW HOLLAND New Holland TF 76 - TF 78 In the autumn of 1994 new combines of the TF series on which the universal computers supervising technology of the thresh were established took root. Engines on these combines were established more powerful of predecessors and these machines were provided with grain bunkers in amount of 9,5 tons....

Artykuł -

Combine harvester NEW HOLLAND TR70

Implementation of new Twin Rotor systems with two longitudinal rotors (1994-2002)Combine harvester NEW HOLLAND TR70 In 1975 it is provided the New Holland TR 70 model which equipped with Twin Rotor system ( two longitudinal rotors rotating in opposite directions). This system replaced classical system with a threshing drum and steaw walker. Combines were equipped with Caterpillar V8 brand engines capacity 165 hp. As alternative...

Artykuł -

Combine harvester NEW HOLLAND TR76 - TR96

Combine harvesters equipped with new cabin designCombine harvester NEW HOLLAND TR76 - TR96 The second generation of combines of the TR76-TR96 series took root into production in 1985. Unlike predecessors these machines were equipped with powerful engines of the Caterpillar brand. These engines had a turbo-supercharging and owned capacity of 240 hp. The new design of a cabin with tinted panoramic glass...

Artykuł -

Combine harvester NEW HOLLAND TR89 - TR99

New Holland combines with self-produced engines (1999-2002)Combine harvester NEW HOLLAND TR89 - TR99 In 1999 the last series of TR combines was provided . These machines were equipped with self-produced engines which differed high profitability of fuel and a good inventory of a torque. The vertical monitor which is on the right removes information on the speed of drum rotation , a level of bunker grain...

Artykuł -

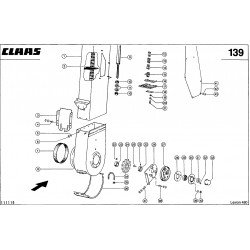

Filling hopper of combine harvester CLAAS...

PrzenośnikiChart of spare parts placement of filling hopper of combine harvester CLAAS Lexion 480

Wykres -

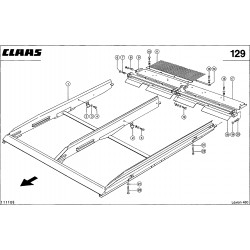

Frame of the top sieve of the CLAAS Lexion...

Inne części roboczeChart of spare parts placement of frame of the top sieve of the CLAAS Lexion 480 combine

Wykres -

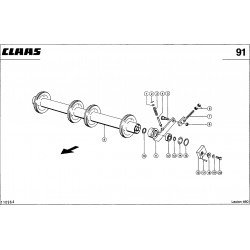

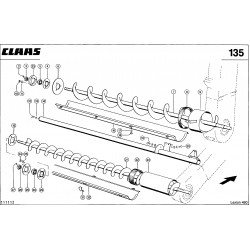

Grain augers of combine harvester Claas...

PrzenośnikiThe layout of the Claas Lexion 480 grain harvester

Wykres -

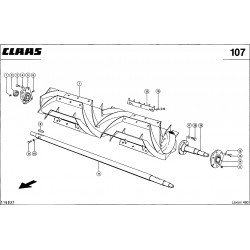

Grain elevator of harvest combines Claas...

PrzenośnikiChart of spare parts placement of grain elevator of harvest combines Claas Lexion 480

Wykres -

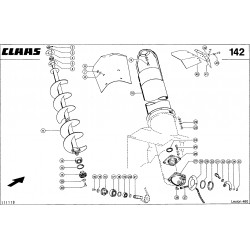

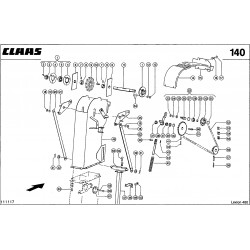

Head of grain elevator of combine CLAAS...

PrzenośnikiChart of spare parts placement of head of grain elevator of combine CLAAS Lexion 480

Wykres -

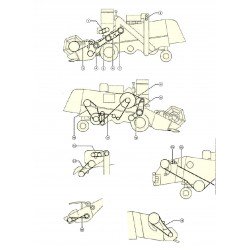

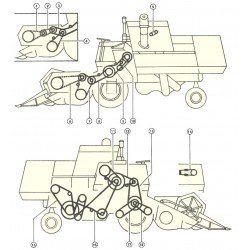

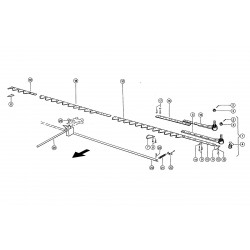

Layout header finger bar (3.9-9 m) combine CLAAS Lexion

Wykres