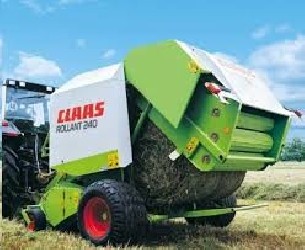

CLAAS balers

In search of mechanics which would cope with a uvyazochny binding devices of bad quality, characteristic the then, brothers Claas in 1921 developed own Knot-weaving device (a so-called knoter). The patent taken out on it became the moment of the birth of the first self-produced agricultural machines of firm CLAAS, the apparatus for binding straw CLAAS. In 1924 they were marked out by a silver medal of the German agricultural society (DLG).

In 85 years which have passed since then Knot-weaving machinery continued were enhanced:

- In 1934 the CLAAS firm issued the first baler of which it wasn't necessary "to feed" any more manually on fields — he selected and "swallowed" vegetable weight

- In 1966 there was the following epoch-making event. CLAAS MARKANT presses the compact, excellently condensed bales of 36 x 40 cm in size under a high pressure.

- 1988 became the next milestone. CLAAS put on the market QUADRANT 1200 — the first press sorter for large-size bales which became the ancestor of absolutely new class of performance.

- After implementation of grinding system ROTO CUT system since 1993 for the first time began possible to make straw crushing directly in the field.

- In 1998 the CLAAS firm once again surprised the market, having offered absolutely new concept of the drive of a baler of QUADRANT 2200

- In 2001 of CLAAS offers to market the FINE CUT – the equipped 49 knifes crushing mechanism for small cutting of straw

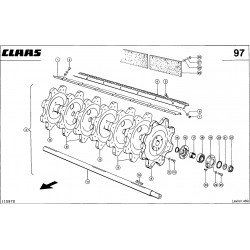

Plant of CLAAS firm on release of press sorters in the French city of Metz — the most modern in Europe. More than 400 workers are tirelessly occupied here with search of most high quality, the most advanced technologies and optimum decisions. Everything that here is designed, in the beginning is exposed most that is to strict check on endurance on our proving grounds round all globe — after all for us the harvest season lasts all 12 months in a year. Thus we don't rely at all at random: in our machines nodes and self-produced components as, for example, a legendary knotter of CLAAS, two which million copies already work at fields of the whole world are used mainly. That the most modern robots in completely automatic mode weld in factory shops, in summary shall pass still the most strict check at test benches. Here as it is possible is more close to the truth operating modes and conditions are imitated, and also the measured values register in memory always to have near at hand the data which are so necessary for further enhancement of equipment. After all only finally all these numerous technological details and specifications naturally lead to that so profitable allocates CLAAS firm: to uncompromising quality which, in turn, opens for us all new and new horizons.