Combine harvester CLAAS SUPER

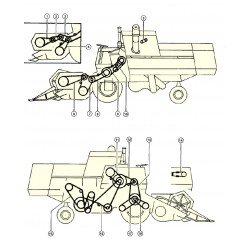

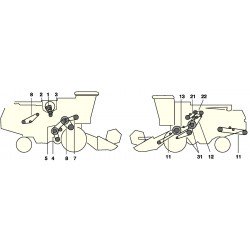

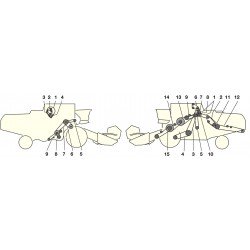

The mower-thresher-binder with its cross-flow principle soon reached the limits of its performance. As early as 1942, CLAAS engineers pressed ahead with the development of a combine harvester based on the cross-longitudinal flow system, in which the grain is threshed in the cross flow and delivered from the machine in the longitudinal flow.

Initially developed under the name super model mower-thresher-binder, this trailed combine harvester entered series production from 1946 under the name SUPER. Thanks to the trailed combine-harvesters of "Super" model and her younger brother - "Junior" (from 1953 on) model company «Claas» started the first combines that were suitable to the needs of farms in Europe.

Because of development of the L-shaped flow of weight, combines performance increased significantly. Combines with system of L-shaped flow of grain determined production of combine-harvesters for the many years.

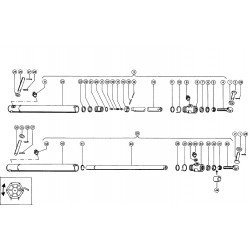

The SUPER combine harvester, with its revolutionary lightweight construction, was continuously revised and enhanced. The machine was equipped with groundbreaking hydraulic control, for instance, from 1958 under the name AUTOMATIC. The system enabled the vehicle operator to control the basic settings of the trailed combine harvester using a hydraulic spool valve on the tractor. The SUPER delighted customers over the years with its high productive capacity, efficiency and reliability. More than 65,000 units of SUPER combine harvester family had been built in Harsewinkel and sold till 1978.