Combine harvesters Massey Ferguson

Combines Massey Ferguson gained international fame thanks to its unique patented threshing system and separation with the transverse rotor. This system effectively proved itself in high-yield crops of corn and soybeans.

Beginning

History of the company Massey Ferguson began in 1847, when Canadian farm owner Daniel Massey in Newcastle, Ontario (Canada), started to produce and repair cars for neighboring farms. At that time the company had a completely different name - Newcastle Foundry and Machine Manufactory. And one of the first in the world became involved in assembling mechanical harvesting, initially using parts from the United States, and later - designed and built its own machinery.

Family business

After the death of the owner the firm was taken over by his eldest son - Hart Massey, who greatly expanded the production. Hart Massey’s sons - Charles, Chester, Walter and Fred - were active participants in the business of their father and eventually replaced him as a leader. But it was the last Massey generation engaged in the family business - the other heirs decided not to follow in the footsteps of their ancestors.

Mergers and development

Massey could not miss the other market leader - Harry Ferguson Limited and to become even stronger, decides to buy the tractor business. In 1891, the merger of Massey Manufacturing Co. and A. Harris, Son & Co. Ltd, which resulted in the formation of Massey-Harris Co. Soon, the corporation became the largest supplier of agricultural machinery throughout the British Empire. In 1930 the company presented a self-propelled harvester.

In 1946, started producing tractors Ferguson TE-20, which is broke all records for the number of sales - 520 thousand cars.

In 1953 the firm merged with the Ferguson Company, and received a new name - Massey-Harris-Ferguson. In 1958, the company won its last title. Together with shortening its name to Massey Ferguson, the company also tried to bring together the two product lines and dealer network. By the end of 1957 the company employed more than 21,000 workers. A lot of offices opened in Europe, which helped to increase sales. Appeared warehouses near Paris, a factory in Germany. The tractors have started to be painted in corporate colors - red and gray, on their sides appeared the logo - three triangles.

In 1953 the firm merged with the Ferguson Company, and received a new name - Massey-Harris-Ferguson. In 1958, the company won its last title. Together with shortening its name to Massey Ferguson, the company also tried to bring together the two product lines and dealer network. By the end of 1957 the company employed more than 21,000 workers. A lot of offices opened in Europe, which helped to increase sales. Appeared warehouses near Paris, a factory in Germany. The tractors have started to be painted in corporate colors - red and gray, on their sides appeared the logo - three triangles.

1962 was the year of the creation of the multipower gearbox.

In 1970, the manufacturers paid special attention to the safety of their combines and tractors. Modernized cabins of the machinery. Besides, constantly improving technical characteristics of aggregates. Massey Ferguson are legislators of progress in its field. Their plows, harvesting machines and presses amaze with their impressive specifications. The company is rapidly gaining markets in Eastern Europe.

1972 marked with the launch of the largest in North America harvester Massey Ferguson 760.

1977 appeared header Power Flow, and a year later was introduced the first electronic control of canopy mechanism.

In 1994 the company bought Massey Ferguson Corporation AGCO.

In 2009, Massey Ferguson engineers developed the agricultural project concept-car designed for the farm of the future. It will use a sensor that can determine the ripeness of plants for combine to cut off only the ripe ones. While this is just a concept, but it will be implemented in the nearest future - said managers of Massey Ferguson.

2010 - expanded the range of combines releasing Delta family with separating hybrid system MF celebrated its 75th release anniversary of the first self-propelled combine.

Combines

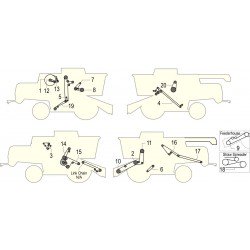

The company Massey Ferguson offers combines of different capacity, performance, design of thresing-separating device and other parameters. Among the variety of products also presented combines with engine capacity from 175 to 459 horsepower and grain tank - of 5000 to 12700 liters. Their production takes place at several plants in the world.

Centora

High quality combines Centora are available in two models MF7280 (378 hp) and MF7282 (413 hp) and are designed to harvest all types of crops. They suit both small and large farms. This model combines are marked with the unique header Power Flow (width from 6.1 to 9.2 m), which has forced flow of stems to the auger. The new system of knife drive from Schumacher increases the number of movements per minute to 1200. The advanced automatic control rotational speed reel.

High quality combines Centora are available in two models MF7280 (378 hp) and MF7282 (413 hp) and are designed to harvest all types of crops. They suit both small and large farms. This model combines are marked with the unique header Power Flow (width from 6.1 to 9.2 m), which has forced flow of stems to the auger. The new system of knife drive from Schumacher increases the number of movements per minute to 1200. The advanced automatic control rotational speed reel.

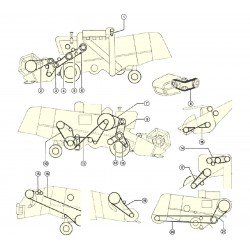

The main threshing drum with improved design, has significant advantages over other threshing systems. Beaters are attached to the drum by means of bolt connections with steel lining. It’s aimed to increase the mass of the drum that keeps the speed and quality of threshing. Concave is done the way to provide high-speed passing through it of mown stems, that increases productivity at lower costs of power.

System of 8-straw walker increases combine performance to 33% compared with 6-straw on turning, scratching and shaking of masses. It improves the quality of separation of grain from straw, and use of simple drive belt would reduce energy and fuel consumption.

In combines is set high performance grain unloading system of rotary type. It provides high-speed and height of the grain tank outfeeding.

Activia

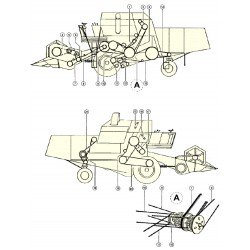

The usage in the combines of highly inert rum allows thresher to cope with any flow of beveled stems and rotary separator improves the separation of grain from wet mass.

For this model of combines is typical:

- Use of the cutting mechanism of the header of Schumacher production (improves cutting process);

- Availability of supplying bitters on the feeder house (provides even removing of beveled stems from the auger and their supply on the drum);

- Galvanized body of grain tract (guarantee continuous operation without replacement of major components).

Thresher is equipped with a concave, which is located under the bitters. This provides additional 14° of coverage on the back side of the main concave. Regulation is depending on the length of straw and humidity, optimizing the process of separation.

Fortia

Combines appeared in the early 2009 and absorbed all the changes and improvements that have been made according to the wishes and suggestions of farmers.

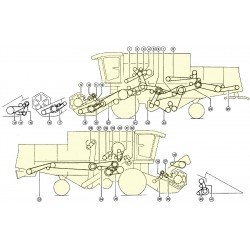

The model MF9695 - 6th class combine with engine power of 330 hp. MF9790 - 7th class combine with engine power of 380 hp. MF9895 - 8th class combine with engine power of 460 hp. On the first two models is mounted engine of 8.4 liters, and on the MF9895 - engine Caterpillar ACERT C13 with the capacity of 12.4 liters. All models are equipped with different headers, width from 6.1 to 11 m (headers MF7200, with floating knife MF8000, Power Flow).

The model MF9695 - 6th class combine with engine power of 330 hp. MF9790 - 7th class combine with engine power of 380 hp. MF9895 - 8th class combine with engine power of 460 hp. On the first two models is mounted engine of 8.4 liters, and on the MF9895 - engine Caterpillar ACERT C13 with the capacity of 12.4 liters. All models are equipped with different headers, width from 6.1 to 11 m (headers MF7200, with floating knife MF8000, Power Flow).

MF9695 has a feeder house with a width of 1.12 m, MF9795 and MF9895 are characterized by more wider feeder house - 1.42 m, providing greater bandwidth. One of the most important advantage of these combines is the availability of supplying beaters, which reduces fuel consumption and grain damage.

The rotors have the same length of 3.56 m and a diameter of 700 mm. In MF9895 rotor with increased up to 800 mm diameter. For greater productivity and better threshing quality all rotors are equipped with the threshing beaters with ability to reverse. Options of installation of the beaters and knives additionally allow you to adjust threshing and separation beveled stems. In turn, hydrostatic rotor drive simplifies combine operation at the varying humidity and weed-infested fields, and reduces power consumption.

Reduction drive equipped with heat system, which reduces the risk of overheating of the node in difficult conditions.

The peculiar feature of rotary combine MF9895 is a quick unloading system of the grain tank - 158 l/sec. All Massey Ferguson combines can be equipped with precision farming system - Fieldstar.

Tractors

Massey Ferguson tractors are presented in different capacities classes from 40 to 280 hp. They can cope with any tasks - whether it’s soil preparation, harvesting, processing plant with protection agents, fertilization...

One of the major advantages of Massey Ferguson wheel tractors is their high performance and versatility, the ability to install at almost any equipment.

Massey Ferguson tractors are produced in modern enterprises, what ensures their high quality and long-term use. In particular, at the plant in the city Canoas in Brazil tractors are producing for 40 years already. Each year, more than 20 thousand tractors come off the assembly line. They are robust and designed for severe operating conditions.

In 1958 the company launched a successful tractor TE-20, which broke all records for the number of sales - 520 thsd. Not less successfully was released in 1978 MF 1505 - the first in the world electronically controlled tractor linkage mechanism (ELC).

Massey Ferguson - is…

Massey Ferguson today - is:

- Over 160 years of innovation and experience

- High-harvesters and self-propelled combines

- One of the leading tractor brands in the world, with one of the most complete lineups

- Compact tractors with the professional attachments for mechanization in the vineyards, fruit gardens, parks and public services

- telehandlers

- Balers

Massey Ferguson is a true global brand, recognized worldwide not only for its rich heritage and experience, but the technological leadership and wide range of products. From product quality to genuine reliable and highly professional sales service - the real value of the company's mission Massey Ferguson, which goes back six generations. And as a result - brand leadership in agriculture.