Corn headers OROS

About the company

OROS (Orosh) (Machine-building Unit Orosh of the Closed Joint-Stock Company Linamar Hanger, located predominantly in Canadian ownership) is a producer of agricultural machinery with more than 50 years of work experience. It develops, manufactures (the  Oroshaza plant in Hungary) and implements Claas, John Deere, New Holland, Case IH combine harvesters and many other spare parts and construction equipment in Western, Eastern, Southern Europe, North America, as well as on domestic market.

Oroshaza plant in Hungary) and implements Claas, John Deere, New Holland, Case IH combine harvesters and many other spare parts and construction equipment in Western, Eastern, Southern Europe, North America, as well as on domestic market.

Nowadays Oros products are presented with a wide assortment of headers for any brand of combines, from 4 to 16 inches with a sophisticated and rigid frame design with a large selection of additional options. OROS headers are designed for corn and sunflower harvesting. Taking into account market requirements and consumer requests, the company continuously improves them. In addition to production and product service, much attention is also focused on the supply of spare parts. In the online store agrodoctor.ua is presented a wide selection of spare parts Orosh. Shafts, rollers, connectors, sprockets, knives, chains, plates and many other spare parts for OROS corn headers are available.

The high quality of OROS products is confirmed by the international ISO 9001 system. In addition, the plant has a certificate of environmental protection ISO 14001.

Corn header OROS HSA

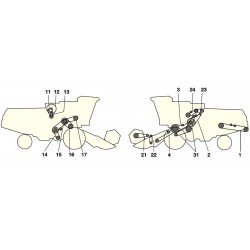

On the basis of the traditional header appointed for the harvesting of corn XCA there was an improvement. So, as a result of fruitful work in 2007 for the first time on the header was installed the front or as it is also called "active" crop lifter (type HSA). It feeds a stem through the  rollers, which is crushed by knives of the cutting unit.

rollers, which is crushed by knives of the cutting unit.

Due to the versatility of the OROS HSA, the stem is harvested and crushed in one pass. The needle is marked by a reliable design with a special form of self-supporting frame, thanks to which it is possible to adjust the row spacing from 70 to 100 cm.

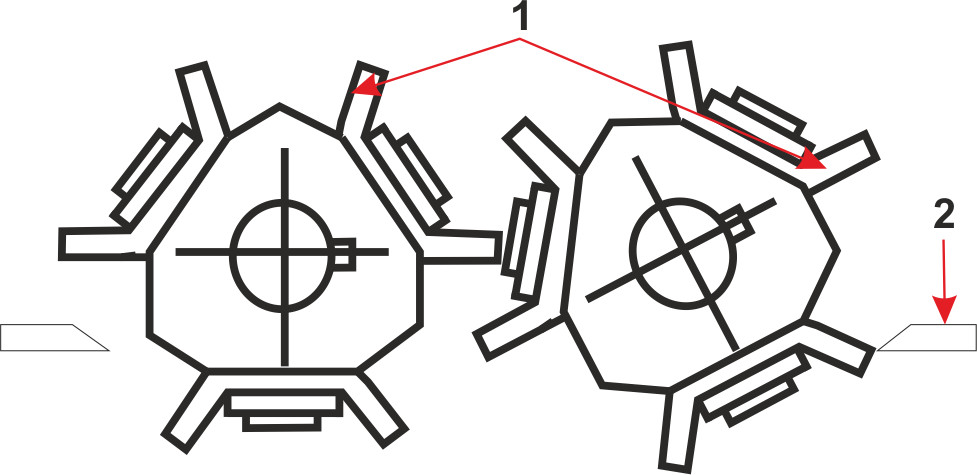

As for the design of the header itself, the corridors are equipped with cast-iron hexagonal cone shaped rollers, help to qualitatively grind the stem mass and, when rotating, create the effect of self-drawing. Rollers are equipped with removable pulling knives, which have a ribbed or flat working plane (6 ribs (1)). The scrubbing plate (2) protects the rollers from winding the stalk mass.

Advantage of the grinding type NSA is that it is located under the stretching rollers (simultaneously with the process of cutting stem masses by rollers, there is a process of cutting the stem with a cutting device 5-7 cm). The cutting mechanism consists of a holder and double-sided knives, which have high-strength material surfacing. The function of the stem lifter can be switched off separately, which allows, when collecting the corn ears, to cut the stem mass for animal feed, or not to stop the harvest by disconnecting the damaged gearbox.

The OROS HSA headlamp is facilitated by plastic separators. The basis of their material is impact-resistant, frost-resistant, extruded polyethylene with high wear resistance. Elastic and streamlined material reduces the probability of damage to the swinging and promotes the absence of corrosion on the separators of the row. The base kit has higher side guides.

The header receives a drive from the propeller shaft of the conveyor, from the sloping combine chamber through the safety sleeve. To prevent damage, the auger has a separate safety sleeve. The drive of the header is equipped with reinforced double roller chains.

Specifications of corn header OROS HSA

|

Type |

During operation |

During transportation |

|||||

|

Width (mm) |

Length (mm) |

Height (mm) |

Width (mm) |

Length (mm) |

Height (mm) |

Weight (kg) |

|

|

4-row 76,2 |

3000 |

2950 |

1190 |

3000 |

1100 |

2230 |

1540 |

|

4-row 70 |

3000 |

2950 |

1190 |

3000 |

1100 |

2230 |

1540 |

|

5-row 76,2 |

3920 |

2950 |

1190 |

3920 |

1100 |

2230 |

1780 |

|

5-row 70 |

3920 |

2950 |

1190 |

3920 |

1100 |

2230 |

1780 |

|

6-row 76,2 |

4720 |

2950 |

1190 |

4720 |

1100 |

2230 |

2020 |

|

6-row 70 |

4720 |

2950 |

1190 |

4720 |

1100 |

2230 |

2020 |

|

8-row 76,2 |

6320 |

2950 |

1190 |

6320 |

1100 |

2230 |

2680 |

|

8-row 70 |

6320 |

2950 |

1190 |

6320 |

1100 |

2230 |

2680 |

Corn header OROS CORNADO

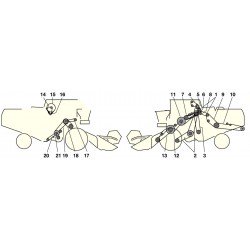

The CORNADO header is a new generation machine, productive and energy-saving.

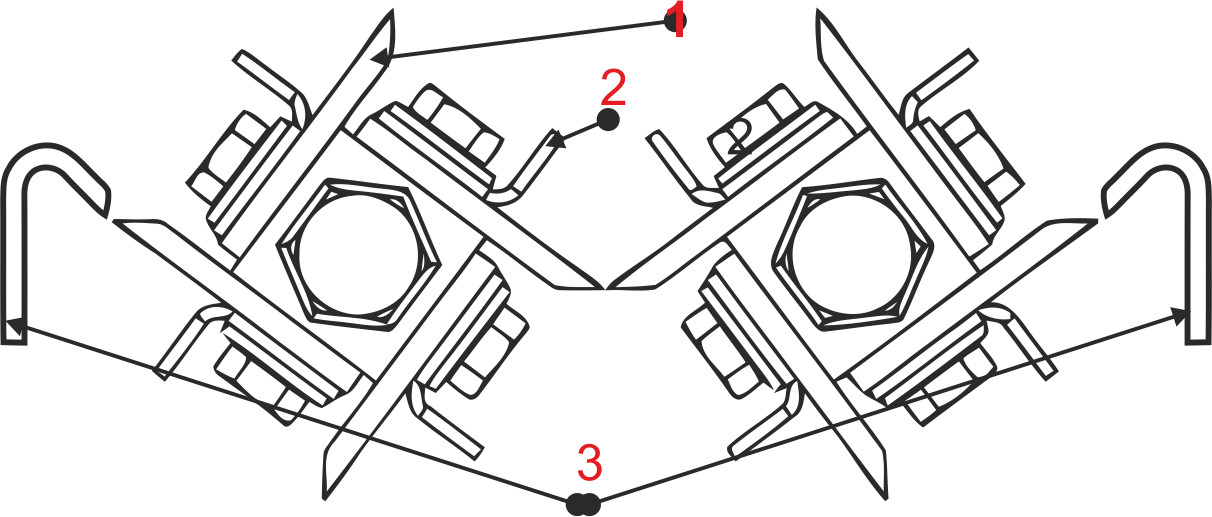

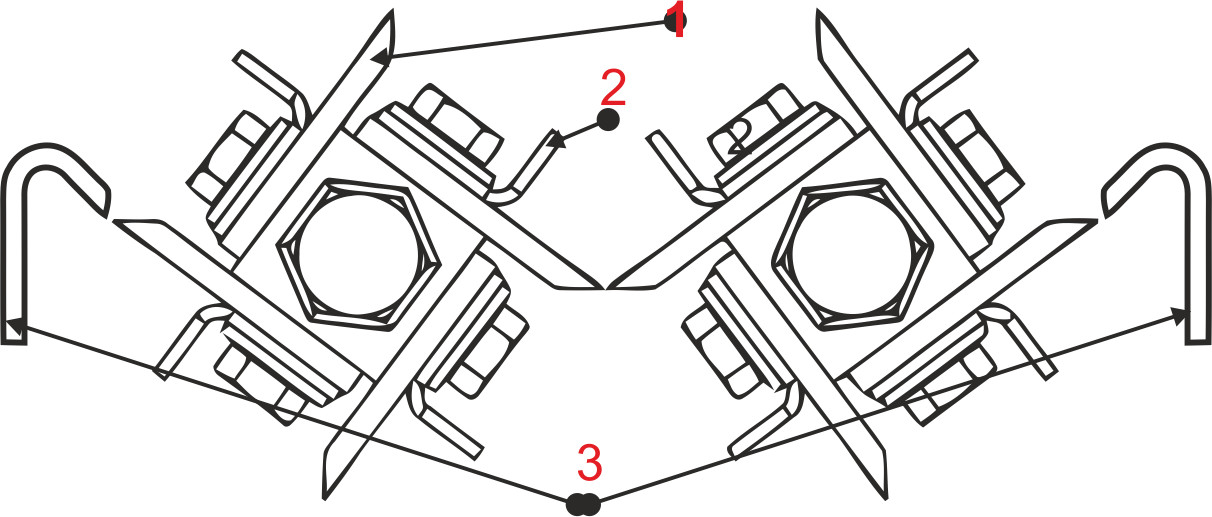

The shape of the pulling rollers of the header has changed on a square cut. However, the feature of this reel is that in addition to the four knives (1), it has four more feed edges (2) and crushing plates (3), which increases the working speed of the assembly to 15-17 km/h. Two roller bearings of a closed type replaced the needle bearing of the tip. The gap between the detachable plates is controlled by the hydraulic mechanism from the combine cabin.

Gearbox housing is aluminum. By reducing the weight of the body installed more powerful bearings, which helped reduce wear of parts, increase the life and safety margins, and thereby reduce fuel consumption. The gearboxes have a safety clutch, which, in case of emergency, does not require replacement or an additional disassembly (for the restoration of its efficiency, it is necessary to only syringe with plastic greases).

The stem crushing system is located at an angle to the stretching rollers, that is, parallel to the ground, what allows you to reduce the cutting height and the fraction of the crushed stem mass to 3-5 cm. The cutting mechanism consists of a holder and double-sided knives, which have

high-strength material surfacing. The function of stem crushing can be turned off, which allows collecting the corn ears to cut the stem mass for cattle feed.

high-strength material surfacing. The function of stem crushing can be turned off, which allows collecting the corn ears to cut the stem mass for cattle feed.

The header has a drive type drive using hypoid gears that do not require maintenance.

The supply chain has received a new automatic spring tensioner of telescopic type that does not require maintenance and adjustments.

On the frame of the header mounted brackets for fastening the stubble protection against damage to the driving wheels of the combine.

The jack has an auto-circuit system that automatically compensates for the inequality of the ground and regulates the minimum cut height. The system is connected to the hydraulic system of the combine and automatically adjusts the position of the header in the course of movement.

Cornado blades are made in 6, 8, 12, and 16 rows.

Specifications of OROS CORNADO corn header

|

Type |

During operation |

During transportation |

|||||

|

Width (mm) |

Length (mm) |

Height (mm) |

Width (mm) |

Length (mm) |

Height (mm) |

Weight (kg) |

|

|

6-row fixed 76,2 |

4650 |

2580 |

1300 |

4650 |

1300 |

2660 |

2160 |

|

6-row composing 76,2 |

4650 |

2580 |

1300 |

4650 |

1300 |

2660 |

2400 |

|

6-row fixed 70 |

4350 |

2580 |

1300 |

4350 |

1300 |

2660 |

2140 |

|

6-row composing 70 |

4350 |

2580 |

1300 |

4350 |

1300 |

2660 |

2390 |

|

8-row fixed 76,2 |

6180 |

2580 |

1300 |

6180 |

1300 |

2660 |

3110 |

|

8-row composing 76,2 |

6180 |

2580 |

1300 |

6180 |

1300 |

2660 |

3360 |

|

8-row fixed70 |

5750 |

2580 |

1300 |

5750 |

1300 |

2660 |

3060 |

|

12-row fixed 76,2 |

9250 |

2580 |

1300 |

9250 |

1300 |

2660 |

4120 |

|

12-row composing 76,2 |

9250 |

2560 |

1300 |

9250 |

1300 |

2660 |

4370 |

|

12-row fixed 70 |

6580 |

2560 |

1300 |

6580 |

1300 |

2660 |

4050 |

|

16-row fixed 76,2 |

12300 |

2560 |

1300 |

12300 |

1300 |

2660 |

5500 |

|

16-row composing76,2 |

12300 |

2580 |

1300 |

12300 |

1300 |

2660 |

5970 |

Corn header OROS 3 HSA

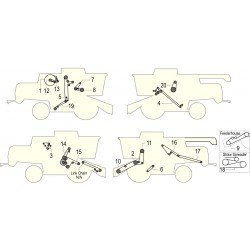

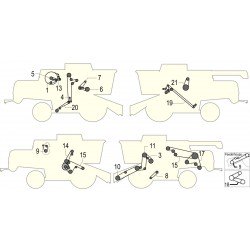

The drive of the gearbox of the header has a single row twenty-fifth chain, which helped the header to get more fast and light, but at the same time reliable, drive. The chain drive became of a closed type, which made it impossible to hit the dust and dirt.

The drive of the gearbox of the header has a single row twenty-fifth chain, which helped the header to get more fast and light, but at the same time reliable, drive. The chain drive became of a closed type, which made it impossible to hit the dust and dirt.

Header OROS 3 HSA black and has a sturdy plastic row divider that is painted in the color of the combine harvester. Yellow - New Holland, red - Case IH, green - John Deer and other combine harvester models.

The harvester frame, like the OROS CORNADO harvester, has brackets for mounting the stubble protection against damage to the driving wheels of the combine harvester.

Specifications of the OROS 3 HSA corn header

|

Type |

During operation |

During transportation |

|||||

|

Width (mm) |

Length (mm) |

Heaight (mm) |

Width (mm) |

Length (mm) |

Height (mm) |

Weight (kg) |

|

|

6-row |

3350 |

2950 |

1190 |

3350 |

1100 |

2230 |

1480 |

|

8-row |

4750 |

2950 |

1190 |

4750 |

1100 |

2230 |

1780 |

Headers OROS are universal because they are aggregated (combined) with combines of any type. High quality work is noted. The minimum amount of technical maintenance required, low weight and low energy consumption all help you save time and money when harvesting.

![08B-2 [Dunlop] Roller chain connecting link](https://agrodoctor.eu/79029-small_extra/x08b-2-dunlop-roller-chain-connecting-link.jpg.pagespeed.ic.umuZ8PRM7i.jpg)

![08B-3 [Dunlop] Roller chain connecting link](https://agrodoctor.eu/79023-small_extra/x08b-3-dunlop-roller-chain-connecting-link.jpg.pagespeed.ic.ZTv_HWDgVF.jpg)

![10B-1 [Dunlop] Roller chain connecting link](https://agrodoctor.eu/79015-small_extra/x10b-1-dunlop-roller-chain-connecting-link.jpg.pagespeed.ic.Jnkm2ehAyW.jpg)

![10B-2 [Dunlop] Roller chain connecting link](https://agrodoctor.eu/79007-small_extra/10b-2-dunlop-roller-chain-connecting-link.jpg)

![12B-1 [Dunlop] Roller chain connecting link](https://agrodoctor.eu/79003-small_extra/x12b-1-dunlop-roller-chain-connecting-link.jpg.pagespeed.ic.6w2hdfGJ0A.jpg)