Combine harvesters John Deere

"I will never put my name on a product that does not have in it the best that is in me." (John Deere - founder and president of the company).

Absolute reliability and efficiency of «Deere & Company» technology, which laid at the stage of development, became the main argument for their products to be chosen not only by farmers from all over the world, but also from Ukraine. For more than 175 years «John Deere» has been the guardian of improvement of the conditions of workers in agricultural sphere which raised from the creation of polished steel plow to the combine harvester 9860 STS. What started it all?

The idea embodied into reality

On the 7th of February, 1804 in Routland, Vermont (USA) with the birth of the third son John in the family of tailor Reynold William Deer. The boy hadn’t been enjoying parental care for a long time – only 4 years. William went by ship to England for heritage, since then John didn’t hear anything about his father.

Having primary education, mother settled her seventeen years old son to assist Magdeburg blacksmith Benjamin Lawrence. During 4 years of studying the student took experience over his mentor and gained significant popularity for inventiveness and mastery. However, the economic crisis that prevailed at that time in Vermont forced the young blacksmith to seek for a better life in Western states. He leaved the family for a while and went in search of better earnings.

After a long and difficult journey, John decided to stay in a small town in Illinois, where he established his own forge. Things were improving. From local farmers Deer found out about significant problems with the processing of viscous soil prairies. Steel plows used at home for tilling of sandy land no longer fit. Thoroughly analyzing the problem, the smith concluded that the correct form and plow blade should lead to their self-scouring of viscous soil. So, in 1837, was created the steel plow of unique design that successfully passed field tests. In 1848 the number of manufactured plows reached 1,000 units per year.

Family affair

Existing for 31 years in the form of company and individual enterprise «John Deere» in 1868 was registered as a legal entity «Deere & Company». A year later to the post of vice-president and later to president was appointed Charles Deere - the son of the founder of the corporation. The new milestone of innovation and change began. Established a few branches, opened a network of independent dealers with small sales techniques. The company «John Deere», in addition to plows, was engaged in manufacturing of cultivators and seeders.

In 1876 registered the trademark «running deer».

In 1876 registered the trademark «running deer».

In 1907, the leadership went to Charles’s son-in-law William Butterworth. In 1918 company purchased the factory which was producing tractors in Waterloo (Iowa) and that was the beginning of the concern in the field of tractor construction.

In 1927 «John Deere» took up for the production of trailed combines.

In 1928, the board passed to John’s grandson – Charles Deer Veyman. Charles counted on engineering, technical mastery of products, improving of existed attributes of agricultural machinery. Even during the crisis, the company was able to sell its products to the tune of $ 100 million.

Deer dynasty was completed by Charles’s son-in-law William A. Hewitt who headed the company for 27 years till 1982. This stage was one of the greatest periods of growth. «John Deere» has become a leading manufacturer of agricultural machinery in the world, and also a major manufacturer of construction and timber collecting machinery and equipment for lawn care.

Quality - above all!

«If we don’t do this, someone else will do it for us, and we will lose business» (John Deere)

The principle of producing of exceptionally high-quality products was basic and priority since the establishment of the company. Millions of farmers and owners of «John Deere» production had the opportunity to verify this. Currently the company has established the highest standards of mastery.

The principle of producing of exceptionally high-quality products was basic and priority since the establishment of the company. Millions of farmers and owners of «John Deere» production had the opportunity to verify this. Currently the company has established the highest standards of mastery.

Thanks to intensive development, global researches and constant quality control of products, it got the honorary name of exceptionally reliable technology with no matter - is it a lawn mower or a modern combine. With the last it’s often associated. And this is not surprising because since 1927 «John Deere» issued more than 1 million self-propelled combine harvesters. Today the company is famous for the series of combines such as: «CWS», «W», «T», «CTS», «STS».

The climax of «John Deere» scientific thought is the flagship line of combines series «STS», which are equipped with bullet rotor. In particular, the brand John Deere 9860 STS is the largest, the most productive agricultural machine of all that have ever been created by the company (output of 375 horsepower, precise control using AutoTrac system combined with satellite navigation system).

Combine harvesters

Main production of combines is concentrated in Illinois, USA (Plant John Deere Harvester Works) and in Zweibrücken, Germany. In 1927 in America was released the first batch of combines and since 1965 started the development of Europe. The main parameters of any John Deere combine harvester are defined and tracked using an electronic system.

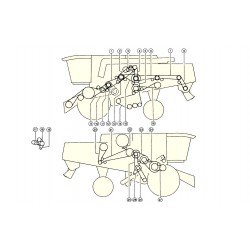

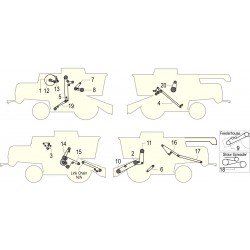

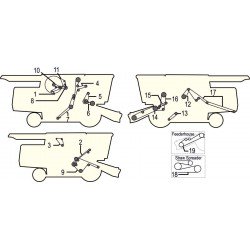

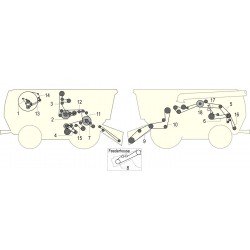

The company offers a wide range of combine harvesters with three different systems of threshing and separation.

Combines with a classic scheme of threshing and straw shakers (W) engine power from 255 to 350 hp. (Zweibrücken) used in areas with high yield. Thanks to drum system of threshing and straw shakers, crops are easily cleaned on cultivated areas with a slope of 22 degrees. Herewith the quality of the straw remains high. Combines of this series are characterized by ease of maintenance, economical fuel consumption and high load capacity.

S Series is different by axial rotary threshing and separation system with a maximum capacity for the collection of wet corn. High comfort workplace.

In Germany, producing 5- and 6-straw combines with the largest threshing area in the world among 6-straw models (T-series) capacity of 290-400 hp. Finger separator and straw walker cope with loads extremely easy.

C Series is characterized by the classical threshing scheme and double-rotor dividing device with a power output of 400 hp. The system of multifinger separation - is a high performance and excellent quality of grain receiving. Combines of this series are used in difficult harvesting conditions. Combiner determines the grinding or drop-straw mode.

Do not remain aloof combines with classic scheme of threshing and straw walker (models 1470 and 1570) from 204 to 262 horsepower.

Tractors

In 1926 in Waterloo was released one of the famous and most popular tractors in tractor-building history - "Clapping Johnny." From here originates the series of R-tractors working on diesel and later machines with six-speed gearbox and hydraulic drive.

6B Series has not only excellent look, but is also reliable and universal. Tractors are equipped with the most necessary functions and nothing more. Good in cultivation.

6B Series has not only excellent look, but is also reliable and universal. Tractors are equipped with the most necessary functions and nothing more. Good in cultivation.

6D Series - style, excellent performance and productivity. Suitable for stockpiling of hay.

6M Series is characterized by high powered engines PowerTech E, panoramic design for the reduction of vibration and total weight of equipment.

7030 Series - high pass characteristics on the road and in the field. There is a new type of power unit - PowerTech Plus which saves fuel. At low engine gears the tractor speed can be maintained at 40 km / h.

В Series is characterized by embedded driving system, control and fix data.

8R / 8RT Series differ by particular endurance and adaptability even to a full night work. Availability of a 9-liter PowerTech and circular lighting system help to achieve maximum performance.

9R Series - AWD (all-wheel drive) tractors designed to work in the toughest conditions without performance reduction.

Unity of the buyer with technology

The future owner of «John Deere» machinery (combine or tractor) may receive an invitation to visit the production shop in the east of Moline (Illinois) or Waterloo (Iowa) to see the purchase during its creation. The visit is planned so that to coincide with the date of production. Presenting a symbolic "golden key", the buyer becomes the first person who starts the engine of purchased machinery.

![Kornelevatorkette - AZ46273 John Deere [Tagex]](https://agrodoctor.eu/91812-small_extra/kornelevatorkette-az46273-john-deere-tagex-.jpg)

![Kornelevatorkette - AZ52338 John Deere [Tagex]](https://agrodoctor.eu/91816-small_extra/xkornelevatorkette-az52338-john-deere-tagex-.jpg.pagespeed.ic.BJTfmM2MM7.jpg)

![Transportkette Einzugskanal AZ46327 John Deere [Tagex]](https://agrodoctor.eu/91813-small_extra/xtransportkette-einzugskanal-az46327-john-deere-tagex-.jpg.pagespeed.ic.j7ONA3LSYV.jpg)

![Transportkette Einzugskanal AZ46328 John Deere [Tagex]](https://agrodoctor.eu/91814-small_extra/xtransportkette-einzugskanal-az46328-john-deere-tagex-.jpg.pagespeed.ic.j7ONA3LSYV.jpg)

![Transportkette Einzugskanal AZ49435 John Deere [Tagex]](https://agrodoctor.eu/91815-small_extra/xtransportkette-einzugskanal-az49435-john-deere-tagex-.jpg.pagespeed.ic.rictMvFY1V.jpg)