Combine harvester CASE IH AFX

In 2004 Case IH unveiled its all new AFX combine line. It replaced the popular 2300 series. Improvements include the new AFT rotor, less belts and chains, more hydraulics and an inverted rotary air screen which gives engine a natural air flow, electronic controlled sieves and screens (programmable), all new cab, longer feeder house, bigger elevators, augers, as well as new updated cosmetics. These machines deliver more horsepower, more productivity and more comfort than ever before. There are only 2 belts and two chains on the machine all hydraulic rotor drive is hydraulic with reverser

The AFX are produced along with New Holland's CR combine with Twin-Rotor technology in Grand Island, Nebraska. The AFX combines will share common parts with the New Holland CR combine including the durable CNH frame, large grain tank from 205 to 330 bushels with foldable extensions and an industry leading 3 bushels per-second (10 liters/sec) unloading rate from an auger that can accommodate heads up to 42 ft.

The AFX Series combines still share a number of proven design elements with the original Axial-Flow introduced in 1977. Axial-Flow combines use a single rotor to thresh and separate grain, and create a vacuum of air that helps provide a clean operating environment. Conventional combines use up to 16 moving parts to do the same job. Because Axial-Flow combines use fewer moving parts, they are easier to operate, more reliable and less costly. The new AFT rotor uses enhanced graduated pitch impellers to promote smooth crop flow and increase rotor throughput capacity in tough conditions by 5 to 25 percent.

The top new CaseIH combine will likely be an AFX 8010, it will be a class 8 combine with around 370hp and a 330 bu (11600 liters) hopper cable of handling up to 42 ft (12.9 m) of header. So in tougher crops the engine will up the hp and in easier crops the hp will drop off to conserve fuel

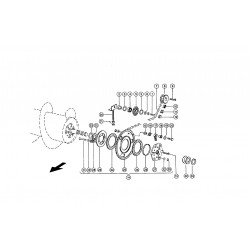

![Feederhouse roller chain 38.4 VB/2K1/J3A [AD]](https://agrodoctor.eu/27124-small_extra/feederhouse-roller-chain-384-vb-2k1-j3a-ad-.jpg)